On 12th Feb nine of us headed down to Southampton to take a 1 day course in outboard engine maintenance.

Many thanks to our Equipment Officer Tobias for suggesting and organising this!

BACKGROUND

Historically our old engines were looked after by Nigel and Keith. Their stellar efforts meant that we got 20 odd years of life out of the things – which was an incredible achievement given the muppets who’ve driven the boat over the years! That solution was never sustainable though and no one else in the branch really knows anything about engines – apart from Aidan who has, rather unhelpfully, moved oop North.

Now that we’ve got nice shiny new engines, and very little engine maintenance knowledge, we’ve decided as a club to get all our servicing done by the professionals. This is fine for now however we all remember how unreliable the old engines were and how it was often necessary to tinker about for ages before the boat would go at the start of a club trip. When our new engines are old and temperamental, will we really abandon every other club trip on the first morning when the engines won’t start? Or should we get ahead of this by building up some basic knowledge that might save some days of diving down the line?

The tipping point was a Portland trip last year where, despite having nice new engines, we had trouble getting going on the first morning and no engineers would answer the phone because there was some stupid boat show going on. The scene in the marina was quite farcical with some people trying to appeal to random other boat users for help, some people googling for YouTube videos about fixing engines, and some people attempting to solve the problem by staring at bits of engine as if they were alien life forms. It was at once obvious to us that, not only could we do very little to help our situation, but we couldn’t even adequately describe the symptoms of the problem down the phone, let alone understand the suggested advice of dibbering the popwobbler to the klangbundler.

Clearly some basic knowledge was required.

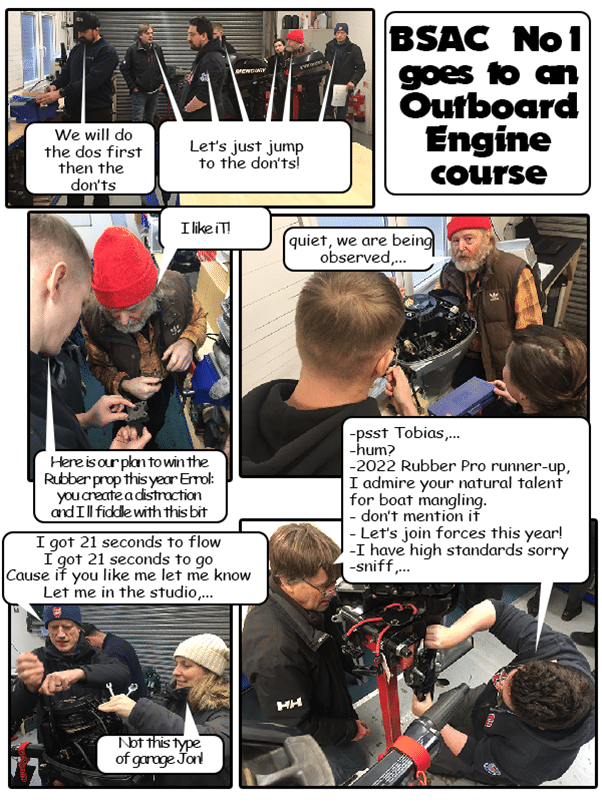

As a final piece of motivation, the day was a chance to get completely covered in oil and take the mickey out of each other for several hours. Excellent.

THE BIG DAY OUT

We arrived in plenty of time to get ourselves a 2nd breakfast (bacon butty in my case) from “The Yellow Welly”. A highly recommendable establishment.

We then had a 3 hour demystification session in which we learnt that carburetta is not a pasta dish impelas are not found grazing on the plains of Africa.

In fact we discovered that engines are quite simple. Air goes in one place and fuel goes in another. They are mixed by the carburetor, burnt to make the engine go, and the result comes out of the exhaust. Cooling water is sucked in by the impeller, goes round the engine and comes out at the centre of the propeller – not from the pee-pee* as I had thought (*credit for Lucie for coining this alterative and much more descriptive name for the tell tale).

If something isn’t working it is therefore probably the case that either air, fuel or water is not flowing properly. Revolutionary! …or not if it’s not working ;).

We then had our lunch break before getting our hands dirty.

Since we were all now experts in the inner workings of outboard engines, they let us loose in the workshop where there were several different makes and models to play with. We were allowed to dissemble and play with whatever we wanted. They clearly had no idea of our boat-mangling credentials!

Martin and I decided to remove and replace an impeller. This was quite fiddly to do as it involved aligning and screwing together 2 halves of a metal shaft at finger-tip reach. I nearly lost a couple of fingers in the process when, part way through this delicate operation, Errol decided to “help” by demonstrating that the top half of the shaft could be moved rapidly up and down via a control at the top! Hmmm – perhaps someone else can do the fiddly bit next time while I “help”.

Laura’s main contribution to our collective learning experience was when she inadvertently discovered which screw to undo if you want to drain all the oil out of the engine. I hope those weren’t her best jeans 😉.

REFLECTIONS AND IMPRESSIONS

The course was a very enjoyable day out and I’d definitely recommend it.

Would I be prepared to do some of these basic maintenance tasks on our engines? Absolutely not! I think it would be well worth taking the hood off though and identifying all the key parts and discussing how these maintenance tasks might be done. I also think it be brilliant to watch while a pro performs these tasks to consolidate the knowledge we have and learn more about the specifics of the engines we’ve got. I don’t know if I’ll ever get to the stage where I’m comfortable doing the annual maintenance on the engines myself, but at least if things go wrong on a trip I’ll have a bit more clue about what the issue might be and what the engineers are talking about.

Tobias is even going to get BSAC to recognise that we have equivalence to the BSAC Outboard Engine Maintainence SDC. That would mean that those of us who are instructors would be able to teach this knowledge to the next generation. I’m not sure where Tobias thinks he’ll get some broken engines for the students to take apart though…